PROFILES

Contact

Phone:+86-13600439689

Fax:+86-755-84616990

Web:www.hzd2007.com

E-mail:hzd@hzd2007.com

How to correctly choose the machine tool fixture for CNC lathe?

Since the end of the 20th century, modern manufacturing technology and mechanical manufacturing process automation have made great progress. In the continuous innovation of machine tool fixtures, its functions are still very significant. Machine tool fixtures have a direct impact on the quality, productivity and product cost of part processing. Therefore, whether in traditional manufacturing or modern manufacturing systems, fixtures are important process equipment. The correct selection of machine tool fixtures is conducive to ensuring the machining accuracy of the workpiece and stabilizing product quality; it is conducive to improving labor productivity and reducing costs; it is conducive to improving the working conditions of workers and ensuring safe production; it is conducive to expanding the scope of machine tool technology and realizing "one machine with multiple functions ".

1. Combined fixture

The combination fixture is also called "building block fixture". It consists of a series of machine tool fixture components with standardized design, different functions, and different specifications and sizes. Customers can quickly assemble various types of fixtures like "building blocks" according to processing requirements. Types of machine tool fixtures. Because the combination fixture saves the time of designing and manufacturing special fixtures, it greatly shortens the production preparation time, thus effectively shortening the small batch production cycle, that is, improving production efficiency. In addition, the combination fixture also has the advantages of high positioning accuracy, large clamping flexibility, repeated use, energy saving and material saving, and low cost of use. For small batch processing, especially when the shape of the product is more complex, the use of combined fixtures can be given priority.

2. Electric permanent magnet fixture

The electric permanent magnet fixture is a new type of fixture designed with new permanent magnet materials such as NdFeB as the magnetic force source and using modern magnetic circuit principles. A large number of machining practices have shown that electro-permanent magnetic fixtures can greatly improve the comprehensive machining efficiency of CNC machine tools and machining centers.

The clamping and loosening process of the electro-permanent magnetic fixture only takes about 1 second, so the clamping time is greatly shortened; the positioning elements and clamping elements of conventional machine tool fixtures take up a lot of space, but the electro-permanent magnetic fixture does not have these space-occupied features Therefore, compared with conventional machine tool fixtures, the electric permanent magnet fixture has a larger clamping range, which is conducive to making full use of the workbench and processing stroke of the CNC machine tool, and is conducive to improving the comprehensive processing efficiency of the CNC machine tool. The suction force of the electro-permanent magnetic fixture is generally 15~18Kgf/cm2, so it is necessary to ensure that the suction force (clamping force) is sufficient to resist the cutting force. In general, the adsorption area should not be less than 30cm², that is, the clamping force should not be less than 450Kgf.

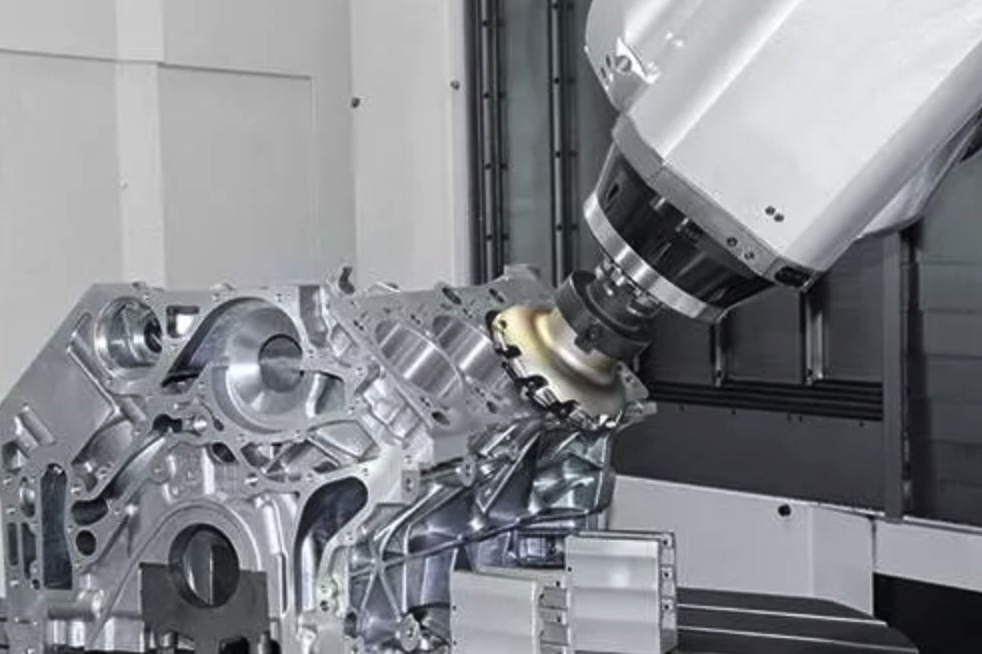

3. CNC machine tool fixtures suitable for mass processing

Hydraulic/pneumatic fixtures are special fixtures that use oil pressure or air pressure as the power source to realize the positioning, support and compression of workpieces through hydraulic or pneumatic components. The hydraulic/pneumatic fixture can accurately and quickly determine the mutual position between the workpiece, the machine tool, and the tool. The position accuracy of the workpiece is guaranteed by the fixture, and the machining accuracy is high; the positioning and clamping process is rapid, which greatly saves the time of clamping and releasing the workpiece. At the same time, it has the advantages of compact structure, multi-station clamping, high-speed heavy cutting, and automatic control.

The above-mentioned advantages of hydraulic/pneumatic fixtures make them especially suitable for use in CNC machine tools, machining centers, and flexible production lines, especially for mass processing.

To sum up, if a CNC processing enterprise wants to ensure the efficiency and quality of processing, it needs to scientifically determine the CNC processing plan according to the actual production and operation of the enterprise, reasonably determine the parameters of the machine tool, the cutting amount and the processing route and other indicators, and do a good job in the design of the fixture Work and abide by the relevant technological process of CNC machining, so as to give full play to the advantages and characteristics of CNC machining and help enterprises achieve higher economic benefits.